CANopen Automation Controller, Top-hat Rail PC or IoT Gateway –

Next Generation Innovation

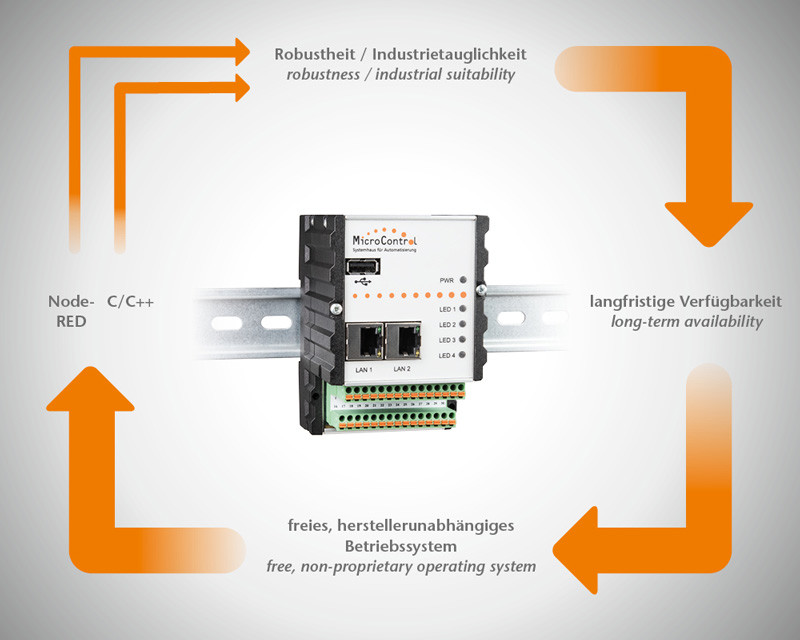

Immerse yourself in the world of advanced control technology with the µMIC.200 family from MicroControl. This pioneering controller goes far beyond the functionality of conventional PLC controllers. As an all in one IoT gateway, CANopen automation controller and top-hat rail PC, the µMIC.200 offers an end-to-end solution. Based on the experience gained from numerous individual customer projects focussing on specific requirements and operating conditions, MicroControl has created the µMIC solution – as an answer to everything that users need in practice.

Flexible

Every company has unique challenges. Whether you use it as an automation controller or IoT-Gateway, the µMIC.200 offers the flexibility to ensure seamless integration into various industrial environments. From production lines to building automation, µMIC.200 is the flexible solution of choice.

Easily programmable with Node-RED or in C/C++

Well-equipped

The freely programmable Linux based control unit µMIC.200 is equipped with an ARM Controller which is clocked at a maximum of 1 GHz. The module provides 512 MByte RAM as well as 4 GByte Flash memory which may be extended via the microSD slot. The maximum power consumption of the modules is 4 Watts.

Highly communicative

Geared towards Industry 4.0 the µMIC.200 is equipped with various digital communications interfaces such as Ethernet, CAN, USB and further serial interfaces. Additional peripherals (e.g. WLAN) may be connected via USB. Equipped with eight configurable digital in-/outputs, a relay, four freely controllable LEDs and a real-time clock the µMIC.200 may be used in a multitude of different applications.

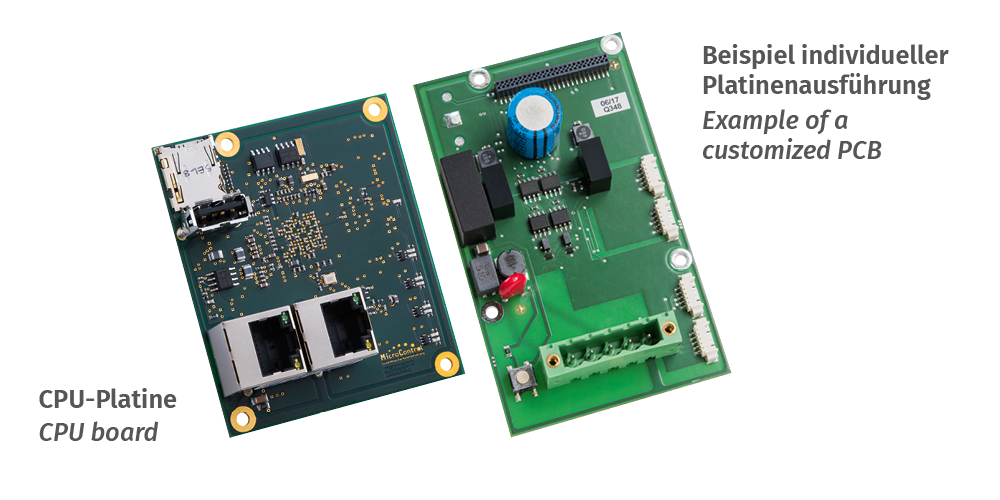

Advantageous two-PCB design

The µMIC.200 can be expanded to meet special needs and, thus, adapted easily to changing operating conditions. The CPU board contains all standard functions, while the second board can be a standard or customized board tailored to specific requirements.

Compact and robust

The µMIC.200 with its casing of only 62 mm in width is ideally suited for DIN top hat rail mounting and is about 25% smaller than common control units. Compared with other control units the µMIC.200 from MicroControl works in a larger temperature range at a wider supply voltage range.

Innovation by Integration

The experience from numerous individual customer projects has gone into the development of our CANopen automation controller. We analysed the specific requirements and operating conditions of our customers’ applications and integrated the findings into our µMIC solution. The result is an automation controller that offers more than conventional PLC controllers.

Comparison with a standard industrial controller

Automation controller µMIC.200

Freely programmable automation controller

Starter kit case

µMIC.200 starter kit

Ready for Industry 4.o

Digitization is the future – and our µMIC.200 is ready for it. The requirements of Industry 4.0 are an integral part of our control solution, which also acts as an IoT gateway. Seamless integration into existing IT structures facilitates efficient communication between different systems to further optimize your production processes.

The µMIC.200 makes the difference

MicroControl stands for innovation and customer satisfaction. With the µMIC.200, we offer not just a solution, but a pioneering experience. Find out how easy programmability, flexibility and integration as an IoT gateway can drive your business forward.

You would like to get more information?

+49 2241 - 25 65 9 - 0

Write an email or give us a call.

Possible fields of application for an IoT gateway, automation controller and top-hat rail PC

What is an IoT-Gateway?

An IoT gateway in the context of fieldbuses acts as a link between various fieldbus protocols and the higher-level IoT infrastructure. It collects data from field devices, translates it into a standardised format and enables seamless integration into the cloud or other central systems. The IoT gateway facilitates communication between different fieldbus systems, improves interoperability and enables efficient monitoring and control of IoT applications in industrial environments.

Top-hat rail PCs in industrial processes

A DIN top-hat rail PC is a specialised computer that has been developed to be mounted on a DIN top-hat rail in industrial control cabinets. Due to its compact design, a top-hat rail PC is particularly suitable for applications with limited space. These PCs are equipped with special fastening elements that facilitate easy installation on a top-hat rail. In industrial environments, top-hat rail PCs perform important control and automation tasks. Thanks to their robustness, they are resistant to vibrations and changes in temperature. The modular top-hat rail PCs offer a wide range of interfaces for seamless integration into industrial control systems. Their flexibility allows them to be customised to the specific requirements of different industrial processes.

Use cases of automation controllers

Automation controllers are compact electronic control devices that are used in automation and controlling of processes in various applications. They typically have a modular structure consisting of a CPU (Central Processing Unit), I/O modules (input and output modules) and communication interfaces. These systems facilitate precise control of machines, systems and industrial processes. Due to their size, automation controllers are particularly suitable for applications where space is limited. They are used in various industries such as manufacturing, building automation, transport technology and agriculture. Automation controllers can take on complex tasks in controlling, monitoring and automation, which means they are an essential part of modern control systems. Their flexibility allows them to be easily adapted to different requirements, they help to increase efficiency and reduce costs in industrial processes.

Learn more

Deepen your understanding of the µMIC.200 controller and its versatile application possibilities as an IoT gateway, CANopen automation controller or top-hat rail PC. Contact us for more information or request a personal consultation.

MicroControl – your partner for next-generation advanced control technology.

Downloads

MicroControl Flyer Control Units

PDF [754 KB]

Virtual Machine 2.04.00

Ubuntu wint C/C++ Cross Compiler

[5.2 GB]

Order a sample

Get a

sample module!

Any questions?

+49 2241 - 25 65 9 - 0

Write an email or give us a call.