SNAP Modules –

Solution for Control Cabinets

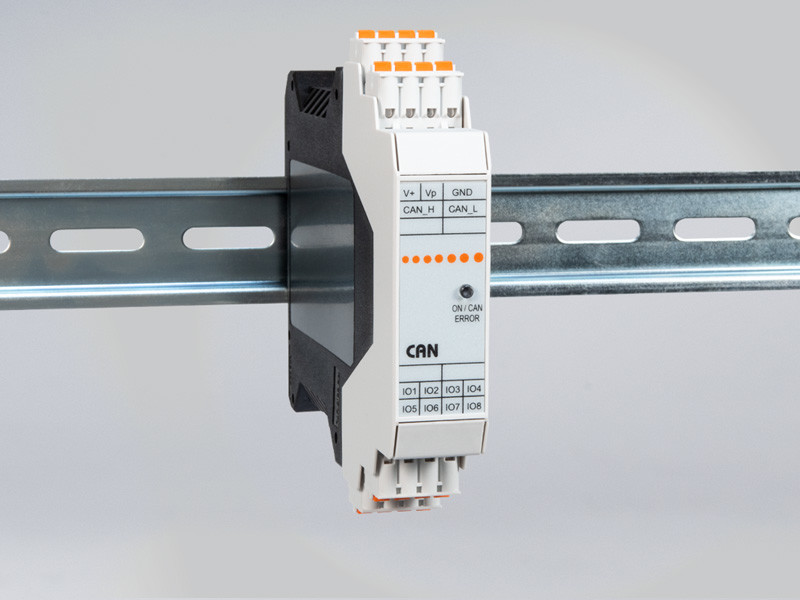

The modules of the SNAP series integrate the advantages and efficiency of digital CAN networks into control cabinets. With its 22.5 mm SNAP casing the modules are ideally suitable for TS35 tophat rail mounting and feature space-saving installation, low weight and a functional structure.

The modules are equipped with a high-speed CAN interface to connect sensors and actuators with a digital CAN network. The CAN interface supports CAN 2.0A as well as CAN 2.0B, which serve the layer-7 protocols CANopen, J1939 and a variety of manufacturer-specific variants (RAW CAN).

Available for a wide range of signal types

A variety of sensors and actuators can be linked with the µCAN-SNAP series:

Signal type

- 1-channel to 8-channel modules

- Analogue inputs +/- 10 V, 0(4)…20 mA

- Analogue outputs +/- 10 V, 0…20 mA

- Analogue inputs strain gauge

- Temperature acquisition thermocouples

- Temperature acquisition Pt100,Pt200, Pt500, Pt1000

- Digital in- or outputs

- Digital counter input up to 500 kHz

- Digital PWM outputs up to 1.5 A per output

Usage

- Control cabinets

- Operating temperatures -40…+85 °C

- Power supply voltage 9…36 V DC

- Tophat rail casing 22.5 mm

- DIN rail mouting TS35

- IP20 ranked

- Status indication by LED

- CE certified

Fieldbus

- Fieldbus CAN / CAN FD

- Protocol CANopen / CANopen FD / J1939 / Raw CAN

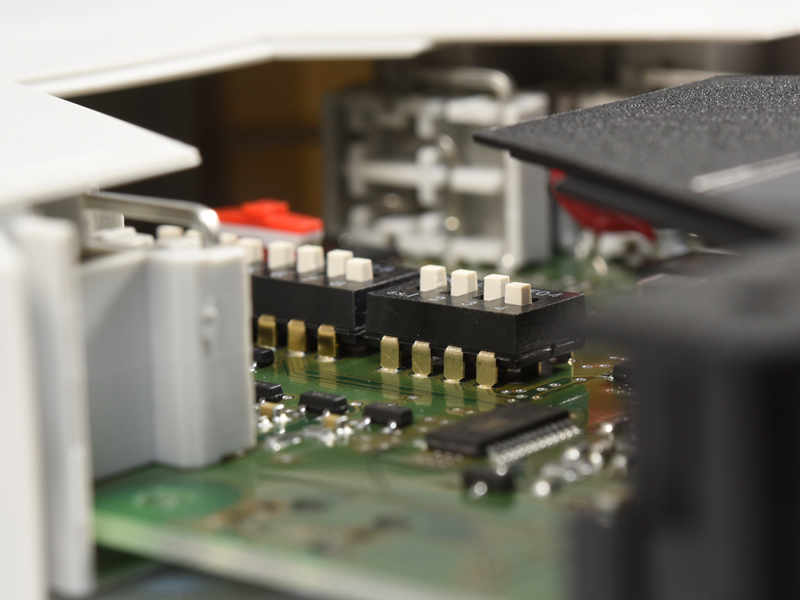

- Bitrate set via DIP-switch

- Module ID set via DIP switch / LSS

- Termination set via DIP switch

The µCAN-SNAP Family

µCAN.1.ai-SNAP

1-channel analogue input current / voltage

µCAN.1.sg-SNAP

1-channel analogue input strain gauge

µCAN.1.ti-SNAP

1-channel analogue input temperature

µCAN.6.ai-SNAP

6-channel analogue input current / voltage

µCAN.8.ti-SNAP

8-channel analogue input temperature

µCAN.4.ao-SNAP

4-channel analogue output current / voltage

µCAN.8.dio-SNAP

8-channel digital I/O input or output

µCAN.8.pwm-SNAP

8-channel digital pulse width output

µCAN.4.ci-SNAP

4-channel digital counter input

µCAN.1.ai-SNAP

1-channel analogue input current / voltage

µCAN.1.sg-SNAP

1-channel analogue input strain gauge

µCAN.1.ti-SNAP

1-channel analogue input temperature

µCAN.6.ai-SNAP

6-channel analogue input current / voltage

µCAN.8.ti-SNAP

8-channel analogue input temperature

µCAN.4.ao-SNAP

4-channel analogue output current / voltage

µCAN.8.dio-SNAP

8-channel digital I/O input or output

µCAN.8.pwm-SNAP

8-channel digital pulse width output

µCAN.4.ci-SNAP

4-channel digital counter input

Easy configuration

Bit rate and module ID are set via DIP switch directly on the PCB, thus facilitating simple operation, higher security and reliability.

Designed for tophat rail mounting

With its 22,5 mm in breadth, the SNAP-series casing is designed to meet the requirements of modern industrial applications regarding space-saving rail mounting, low weight and a functional structure

Highspeed CAN interface

The modules are equipped with a CAN interface and support the protocols CANopen / CANopen FD / J1939 / Raw CAN and a variety of manuacturer-specific variants.

Connectivity

All signal lines are conntected to the device via plug-in connectors as screw or spring-cage connectors which facilitates quick and easy installation.

Downloads

MicroControl Flyer I/O Modules

PDF [1 MB]

Order a sample

Get a

sample module!

Any questions?

+49 2241 - 25 65 9 - 0

Write an email or give us a call.