Control Units

Freely programmable

Control Unit

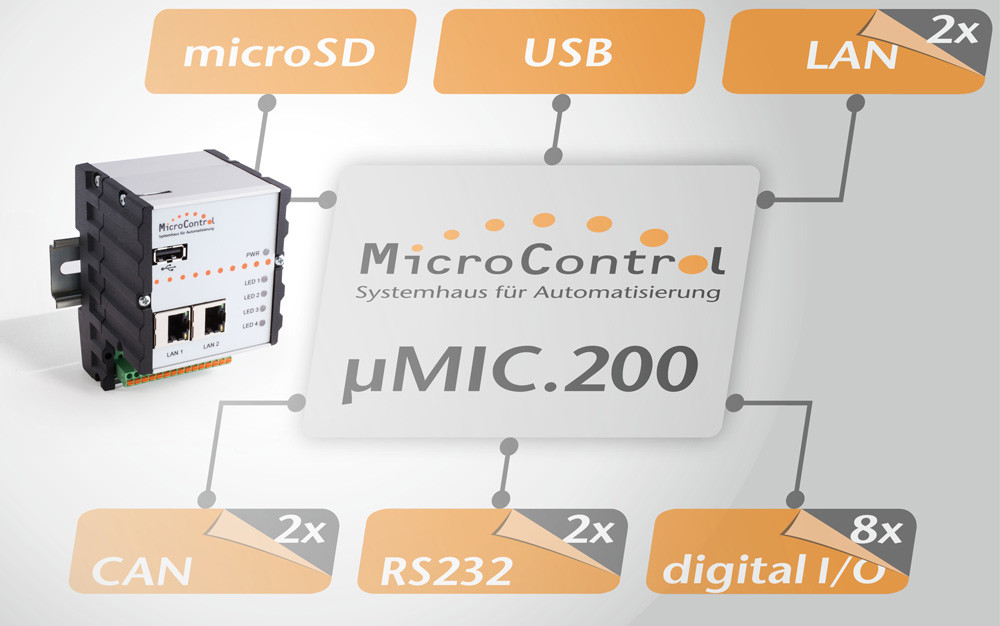

µMIC.200

Real-time Linux, Ethernet, CAN, USB plus custom electronics in a space-saving metal top-hat rail casing. In its µMIC.200 family, MicroControl integrates the best of the world of automation for IoT/Industry 4.0. The unit is equipped with COMBICON® connectors and offers versatile connection facilities for digital signals, CAN bus and RS-232. I/O modules with CAN interface can be connected to the unit via the integrated CANopen FD Master library.

An even higher flexibility is offered through its customizable electronics. Two boards perfectly matched. CPU board and high performance standard board or – alternatively – a CPU board and a custom board tailored to your specific needs. The metal casing is able to withstand extreme operating environments. And all this at most favourable terms.

Features

- 2 Ethernet interfaces

- 2 CAN interfaces (isolated)

- 2 x RS-232 (isolated)

- CANopen Master function

- Cortex-A8 CPU with USB interface of 1 GHz frequency

- 4 GByte Flash and 512 MByte DDR3 RAM

- FRAM memory (battery-free)

- Memory extension via microSD card

- Operating temperature range -40 °C … + 85 °C

- Power supply voltage 9…36 V DC

- DIN rail mouting TS35

- Metal casing

Ordering Information

Freely programmable control unit in metal casing for DIN-rail applications. This ARM based platform can be programmed with Node-RED or in C/C++.

Contains: µMIC.200 control unit, mains adapter, CANopen I/O module, connecting cable

Downloads

Datasheet, Rev. K

Control unit µMIC.200

PDF [270 KB]

Flyer Control Systems

PDF [736 KB]

Virtual machine 2.04.00

Ubuntu with C/C++ cross compiler

[5.2 GB]

Handout Control Units µMIC.200

PDF [1 .8 MB]

Sample order

Get a

sample module!

Any questions?

+49 2241 – 25 65 9 – 0

Write an email or give us a call.