Solutions for construction machinery

Reliable measurement, controlling and monitoring.

µCAN-BOX

For harsh environments

Solutions for power generation

high temperatures – challenging dynamics.

F1 Module

Perfectly suited for mobile data acquisition

I/O Modules TRS: Precise Measurement in E-Bikes

The requirements modern e-bikes have to fulfill are growing – and with them the need for precise, reliable measurement technology. I/O modules from MicroControl’s TRS series are used for testing and development purposes.

For example: acquisition of analogue signals on a brake.

Smart E-Bikes: CAN Bus Communication

Today’s e-bikes are more than just bicycles with an electric drive – they are intelligent systems.

Motor and display communicate via CAN bus which ensures smooth, secure data transmission in real time.

…and also: Training CAN Bus and CANopen

Expert knowledge and hands-on tips and tricks for beginner and advanced users will facilitate and speed-up your development processen.

And you can take part easily from home – or wherever you happen to be …

Next dates:

08 + 09 July: CAN Bus Basics

15 + 16 July: CANopen

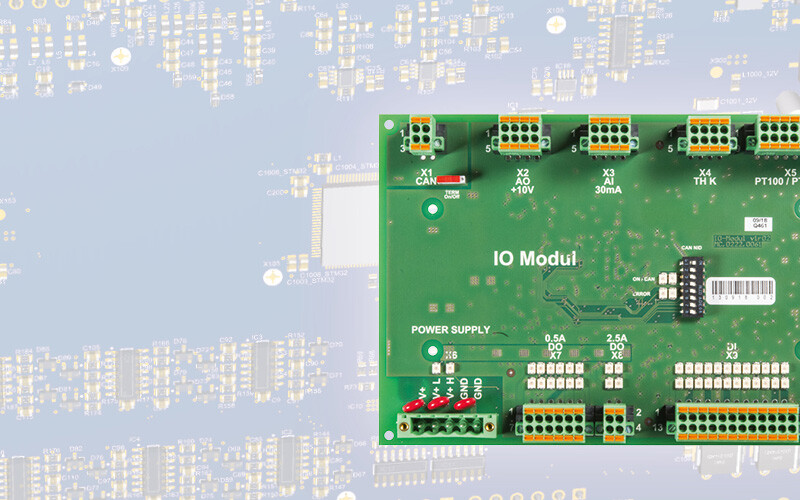

I/O Modules

Digitize analogue pressure and temperature data; significantly increased performance and safety in comparison with conventional industrial electronics; standard modules, individual specifications, OEM versions, software, accessories.

Control systems

Protocol stacks

Training

Advisory Service

Development